The Austrian company is a global market leader in the development and production of systems and components for plastics recycling. For more than 40 years, it has been committed to researching and developing technologies for ever more efficient and environmentally friendly machinery.

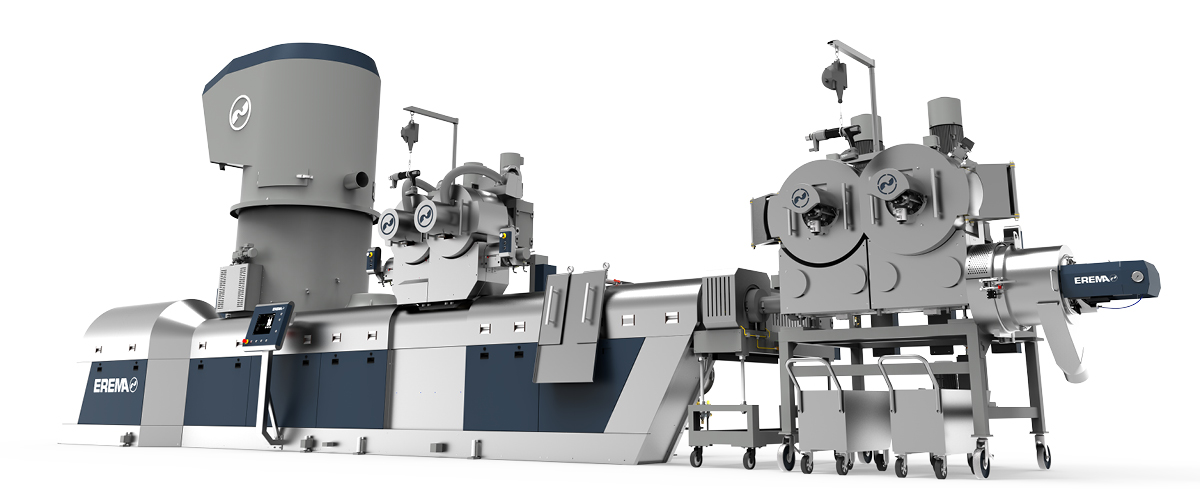

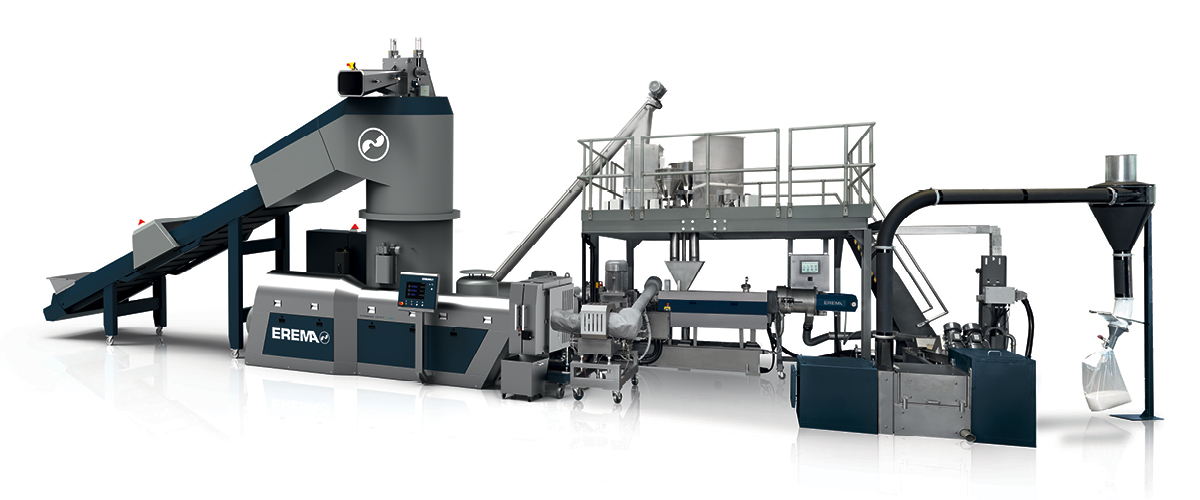

EREMA systems are considered standards in plastics recycling due to their quality, durability and high degree of reliability. Worldwide there are more than 7000 EREMA systems producing more than 18.5 million tonnes of high quality granulate yearly.

EREMA offers a portfolio of complete recycling systems:

- for all thermoplastics such as PE, PP, PET, PS, ABS, PA, PC, biopolymers and compounds

- in a wide variety of forms such as films, containers, foams, fibres and tapes

In the company’s state-of-the-art Customer Centre, which covers an area of 1,200 square metres, customers can carry out trials with EREMA recycling systems, using their own materials under real production conditions, in order to identify the optimum configuration for the specific requirements.

The heart of the EREMA systems is the densifier/compactor: the efficient preconditioning unit required for a stable end product. This is due to the continuous self-adjustment in line with the incoming material: a dynamic unit that does not require the fixed presence of operators. In this way, the material is perfectly prepared for passage into the single-screw extruder tangentially connected to the densifier. The densifier is used to compact, homogenise, heat, dry and dose the material.

In the past, the materials in the densifier/compactor rotated in the same direction as the extruder. EREMA’s revolutionary patented Counter Current technology changes the direction of rotation within the densifier/compactor so that the material rotates in the opposite direction to the extruder. It is a simple but very effective effect, as the extruder processes more material in less time. Thanks to a different design of the inlet zone in the extruder, the flow rate remains consistently high within a wider temperature range in the densifier/compactor.